Understanding the environmental footprint of silicone kitchenware is crucial for making sustainable choices. How does the production process influence its overall impact?

The production of silicone involves several stages that affect its environmental footprint, from raw material extraction to manufacturing and recycling.

When I first delved into the lifecycle of silicone kitchenware, I discovered both the challenges and innovations that shape its sustainability. This knowledge has been instrumental in making informed decisions for our products.

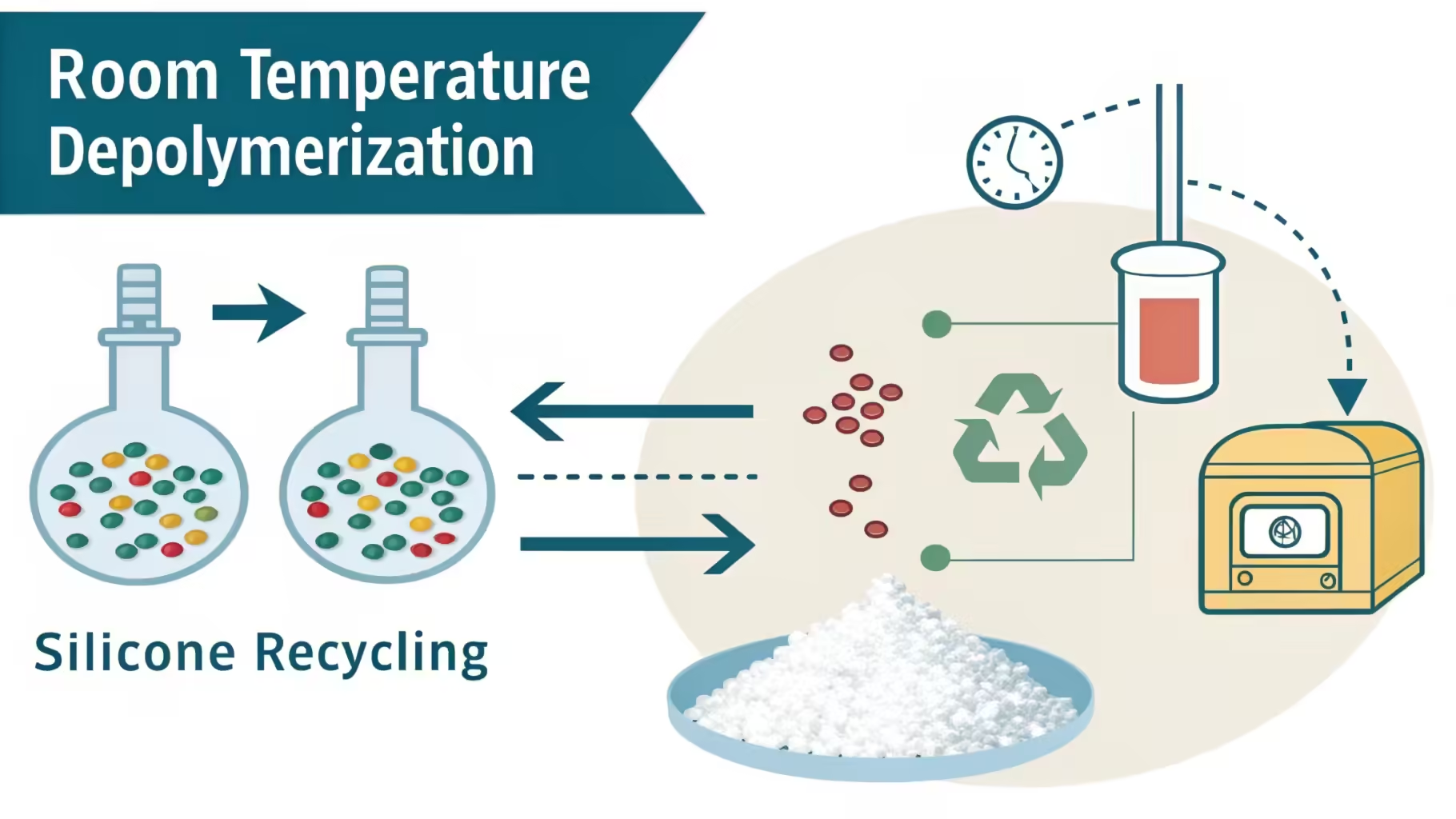

How Does Room-Temperature Depolymerization Work for Silicone Recycling?

Room-temperature depolymerization is an innovative method that simplifies the recycling of silicone, making it more environmentally friendly.

Room-temperature depolymerization breaks down silicone into its monomers without the need for high temperatures, reducing energy consumption and making the recycling process more sustainable.

The Process of Room-Temperature Depolymerization

- Catalyst Addition: A catalyst is added to the silicone material to initiate the depolymerization process.

- Molecular Breakdown: The silicone polymer chains are broken down into smaller molecules or monomers at ambient temperatures.

- Purification: The resulting monomers are purified for reuse in producing new silicone products.

Advantages of Room-Temperature Depolymerization

| Advantage | Description |

|---|---|

| Energy Efficiency | Significantly lower energy requirements compared to traditional methods. |

| Reduced Emissions | Minimizes greenhouse gas emissions during the recycling process. |

| Scalability | Easier to implement on a large scale due to lower operational costs. |

Impact on Environmental Sustainability

Room-temperature depolymerization not only conserves energy but also reduces the overall carbon footprint of silicone recycling. This method supports a more circular economy by enabling the continuous reuse of silicone materials.

What Are the Potential Applications of Recycled Silicone?

Recycled silicone can be repurposed into a variety of products, enhancing its sustainability and reducing waste.

Recycled silicone can be transformed into new kitchenware, medical devices, automotive parts, and even construction materials, demonstrating its versatility and environmental benefits.

Diverse Applications of Recycled Silicone

- Kitchenware: New silicone kitchen tools, molds, and storage containers.

- Medical Devices: Reusable medical equipment like tubing and seals.

- Automotive Parts: Components such as gaskets and seals that require durable materials.

- Construction Materials: Weather-resistant seals and insulation materials for buildings.

Benefits of Using Recycled Silicone

| Application Area | Benefits |

|---|---|

| Kitchenware | Maintains the flexibility and durability of silicone. |

| Medical Devices | Ensures safety and reliability through high-quality recycled materials. |

| Automotive Parts | Enhances the sustainability of automotive manufacturing. |

| Construction | Provides eco-friendly alternatives to traditional materials. |

Case Study: Recycled Silicone in Kitchenware

A leading kitchenware brand successfully integrated recycled silicone into their product line, resulting in reduced production costs and a lower environmental impact. Consumers have responded positively to the eco-friendly products, driving sales and promoting sustainability.

How Does the Energy Efficiency of Silicone Recycling Compare to Traditional Methods?

Energy efficiency is a critical factor in evaluating the sustainability of silicone recycling methods.

Silicone recycling methods like room-temperature depolymerization are more energy-efficient compared to traditional high-temperature recycling processes, leading to lower overall energy consumption and reduced environmental impact.

Comparison of Recycling Methods

| Recycling Method | Energy Consumption | Environmental Impact |

|---|---|---|

| Traditional High-Temperature Recycling | High | Significant carbon emissions |

| Room-Temperature Depolymerization | Low | Minimal emissions, energy-efficient |

| Mechanical Recycling | Moderate | Moderate energy use, some emissions |

Benefits of Enhanced Energy Efficiency

- Cost Savings: Lower energy requirements reduce operational costs for manufacturers.

- Environmental Protection: Reduced energy consumption leads to fewer greenhouse gas emissions.

- Sustainable Production: Supports the development of more sustainable manufacturing practices.

Future Directions

Advancements in recycling technologies continue to improve the energy efficiency of silicone recycling. Research into alternative catalysts and process optimizations aims to further reduce energy usage and enhance the sustainability of recycled silicone.

Are There Any Commercial Products Currently Made from Recycled Silicone?

Yes, several commercial products are now being made from recycled silicone, showcasing the material's versatility and environmental benefits.

Recycled silicone is used in the production of new kitchenware, medical devices, automotive parts, and consumer goods, demonstrating its practicality and sustainability.

Examples of Commercial Products

- Kitchenware: Spatulas, baking mats, and storage containers made from recycled silicone.

- Medical Devices: Recycled silicone used in the manufacture of non-invasive medical tools.

- Automotive Parts: Eco-friendly gaskets and seals for vehicles.

- Consumer Goods: Recycled silicone items like phone cases, bracelets, and household tools.

Impact on the Market

The introduction of recycled silicone products has encouraged more companies to adopt sustainable practices. Consumers are increasingly seeking eco-friendly options, driving demand for products made from recycled materials.

Success Stories

| Product Category | Brand Name | Description |

|---|---|---|

| Kitchenware | Silpat | Recycled silicone baking mats offering non-stick surfaces. |

| Medical Devices | MedSil | Recycled silicone tubing used in medical applications. |

| Automotive Parts | FlexSeal | Eco-friendly silicone gaskets for automotive use. |

| Consumer Goods | EcoSil | Recycled silicone phone cases and accessories. |

What Are the Challenges in Scaling Up Silicone Recycling Technologies?

Scaling up silicone recycling technologies presents several challenges that need to be addressed to achieve widespread adoption.

Challenges in scaling up silicone recycling include high initial investment costs, limited recycling infrastructure, and the need for technological advancements to improve efficiency and output.

Key Challenges

- High Investment Costs: Developing and implementing advanced recycling technologies requires significant financial resources.

- Limited Infrastructure: Many regions lack the necessary facilities and systems to support large-scale silicone recycling.

- Technological Limitations: Current recycling methods may not be efficient enough to handle the volume of silicone waste generated.

- Market Acceptance: Encouraging manufacturers and consumers to adopt recycled silicone products can be difficult without adequate incentives.

Potential Solutions

| Challenge | Potential Solution |

|---|---|

| Investment Costs | Government subsidies and private investments to fund recycling initiatives. |

| Limited Infrastructure | Developing partnerships between manufacturers and recycling facilities to build necessary infrastructure. |

| Technological Limitations | Investing in research and development to enhance recycling technologies and increase efficiency. |

| Market Acceptance | Promoting the benefits of recycled silicone through marketing campaigns and consumer education. |

Future Prospects

With increasing environmental awareness and regulatory support, the scalability of silicone recycling technologies is improving. Innovations in chemical recycling and upcycling methods hold promise for overcoming current challenges and making recycled silicone more accessible and affordable.

Conclusion

The production process of silicone significantly affects its environmental impact through resource extraction, energy consumption, and emissions. By addressing these challenges with energy-efficient technologies, innovative recycling methods like room-temperature depolymerization, and responsible disposal practices, we can mitigate silicone’s environmental footprint. Understanding the balance between silicone’s durability and its non-biodegradability is key to making sustainable choices. Embracing recycled silicone not only supports a circular economy but also promotes a greener, more sustainable future for kitchenware manufacturing.